Tenmat Develops an Innovative Wear Material to Revolutionise Cultivation

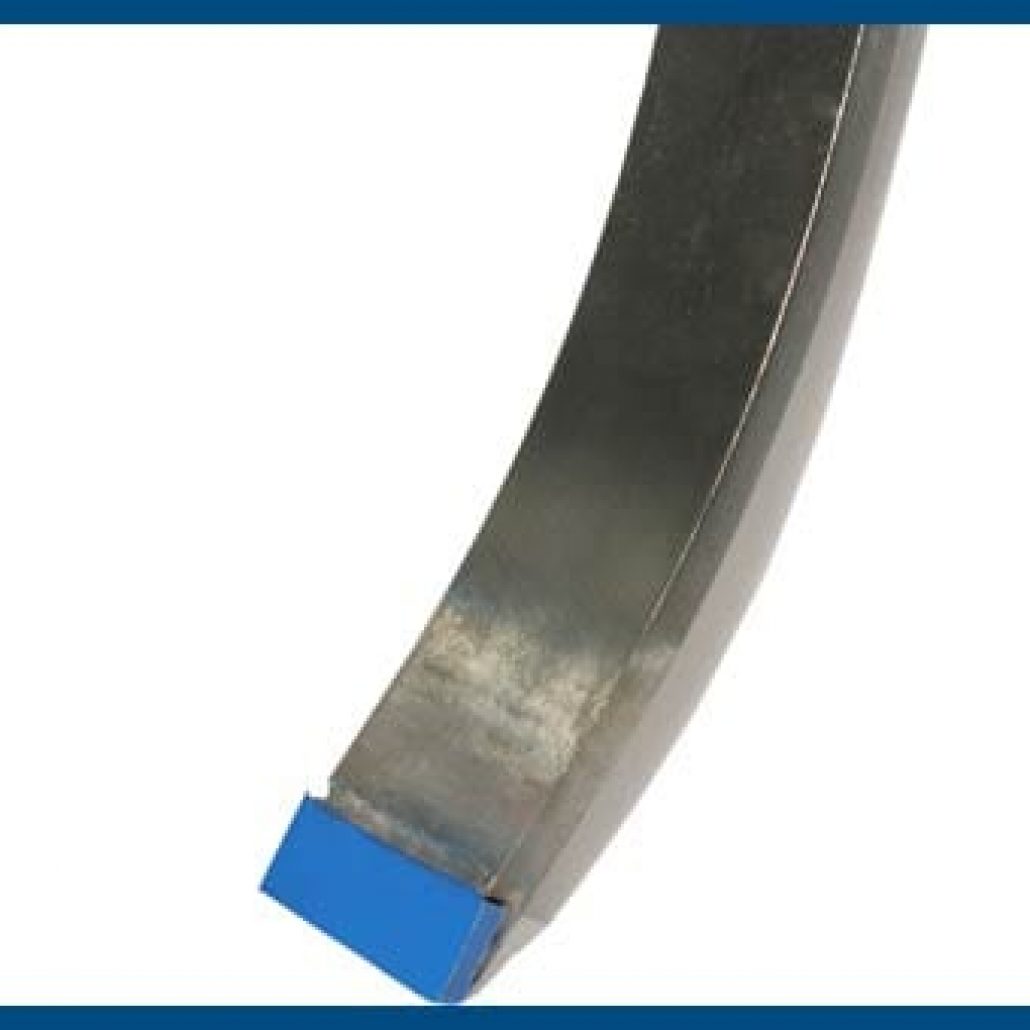

A new, hard-wearing material that is set to revolutionise the way arable farmers maintain their cultivation equipment has been launched by its UK-based manufacturer. Ferobide, developed and produced by Tenmat Limited at its Manchester factory, has all the benefits of tungsten carbide, but none of the drawbacks.

One of Ferobide’s main advantages is that it can be cut and welded on-farm using standard workshop equipment.

The Ferobide Benefits Are:

• it is weldable;

• it offers full point protection;

• it has similar resistance to wear as tungsten carbide;

• it has very high impact strength;

• it has superior resistance to chipping; and

• it is farmer-friendly and easy to cut.

Unlike other tungsten carbide materials, Ferobide uses a reinforced steel matrix to bond the hard tungsten carbide particles together. This gives added toughness, but more importantly allows the product to be welded using standard methods.

The ability to cut Ferobide is not due to it being less hard than other materials; the tiles simply need to be scored with a slitting wheel and then, using a hammer and vice, can be sheared along the score line.

The wear resistance of Ferobide is similar to that of standard tungsten carbides, but its novel ability to be welded now yields a secure attachment to the steel base material. Designed for high strength, Ferobide enjoys extra toughness that greatly reduces chipping – the common disadvantage with other tungsten carbide materials.

Highly Innovative

As with most industry-changing developments, there is a highly innovative and progressive company behind Ferobide’s development. Tenmat is one of the UK’s most successful developers and manufacturers of state-of-the-art materials.

Since 2012 Tenmat’s dedication to quality has twice been recognised with the prestigious Queen’s Award; for Innovation, and for International Enterprise.

Development and manufacture using carefully sourced raw materials takes place at the company’s Manchester plant, where 250 people make some of the world’s most exciting materials – including components for space rockets, supercars and submarines.

Extensive research undertaken at the Tenmat laboratory, alongside long-term field trials covering several thousand acres, has optimised the wear resistance and toughness of Ferobide. The material has been specially developed to solve the needs of the farming industry regarding extension of wear life of all soil-engaging parts. Tenmat has further added the breakthrough that the material can be cut and welded using basic workshop equipment.

No two soil types are the same, and each produces different wear issues. When expensive tungsten carbide points are bought, they can only offer a relative compromise of wear resistance across a number soil types; however, only the farmer fully understands how and where the wear occurs on his points due to his own soil when using his cultivation methods.

The ease of application of Ferobide tiles means they can be readily welded in position to suit exactly how a component is wearing to optimise results. Of course, it should be noted that – like all tungsten carbides – Ferobide is not an inexpensive material. It should only be fitted by an experienced welder, and it is important to ensure that the welds are placed in such a way that they are protected from exposure to abrasive soil and avoid being worn out, which leads to loss of the tile.

| Column 1 | Ferobide | Tungsten carbide |

|---|---|---|

| Attachment to steel | Readily welded with standard equipment | Can only be brazed by specialists |

| Impact resistance | Highly resistant to chipping and breakage | Low resistance to impact, so is easily chipped |

| Cutting | Readily achieved with a standard cutting wheel and basic tools | Expensive and highly specialised |

| Delamination | Welded joints are significantly stronger than brazed joints | Braze can fail and the tile lost |

Agricultural cultivation equipment needs to work faster, longer and more efficiently than ever before to minimise downtime and maximise crop yields.

During the past decade, tungsten carbide wear parts have been shown to be unrivalled when it comes to wear resistance and maintenance of the critical wear part profiles needed to optimise crop establishment, however tungsten carbide has a number of real problems that Ferobide has now solved.

Consequently, a number of machinery manufacturers are already using Ferobide to prolong the component life and maintain optimum profiles, so it is worth asking for the Ferobide option.

Tenmat specialises in bespoke components machined to customer requirements. The company is proud to offer a fully tailored service to its customers and, as such, it is in the enviable position of being able to manufacture chip-resistant wear protection to your needs.

The company regularly supplies free samples of new Ferobide tiles upon request from potential customers suffering from difficulties faced due to inferior wear protection.

For more information on Ferobide, visit: www.ferobide.co.uk; email: ferobide@www.tenmat.com; or call 0161 872 2181.

Press Contact:

Rupert Coggon

Business Development Director

Tenmat Ltd

Tel: 0161 955 2425