Tried. Tested. Cost-Effective.

- Home

- High Temperature Solutions

- Glass Production

Glass production materials

Tried. Tested. Cost-Effective.

tried and tested

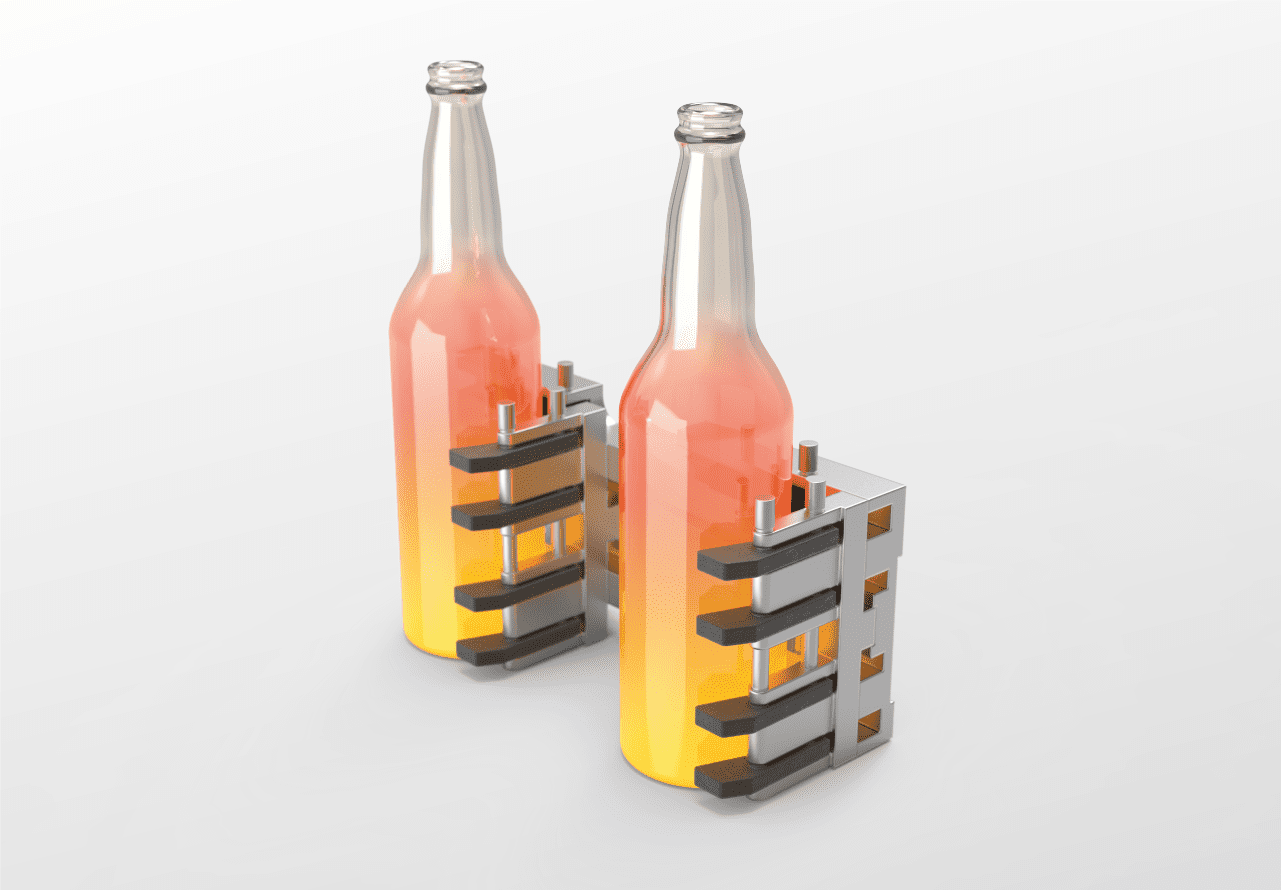

High performance materials for glass production

Tenmat has been a supplier of high-performing materials for the glass industry for decades. Whether for conveying surface critical flat glass in the float glass process or for the high-paced container glass production lines, our products improve the quality of glass products, reduce maintenance needs and improve throughput.

CERAMIC CARBIDE MATERIAL

Vitronus

Using material science techniques, Tenmat has been able to develop a carbide ceramic material that lasts up to 5 times longer than wear parts made from competing materials, which means less downtime replacing parts and less spent on replacing them. That material is Vitronus.

Vitronus at a glance

With Vitronus, hot-end container glass plants will be able to:

-

Improve the

melt-to-pack ratio

- Reduce the consumption of spare parts

- Reduce the number of glass rejects

- Improve efficiency and productivity