Interchangeability conditions defined in UIC 510-1 for 2 Axle Bogies and Railko Composite Liners

Elaborated by Ciprian Ciucur

1. Overview

UIC 5190-1 is defining the design and manufacturing conditions that must be fulfilled first, and then later on in maintenance and repairs, for interchangeability of 2 axle bogies.

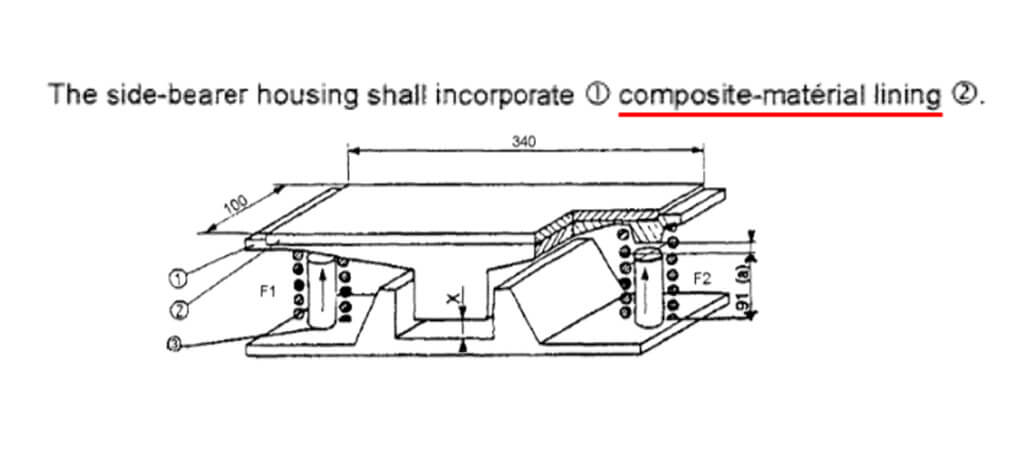

The conditions specified on page 10 chapter 7, and references to (RAILKO) composite material can be seen on Appendix 8 of UIC 510 – 1.

Before going in more detail that will help us understand what UIC 510-1 defines as mandatory conditions for 2 axle bogies, we need to learn the difference between plastic and composite material. Most people in the rail industry make a huge mistake by considering a composite material as equal or same material with plastic.

2. Is composite plastic? Basic Definitions

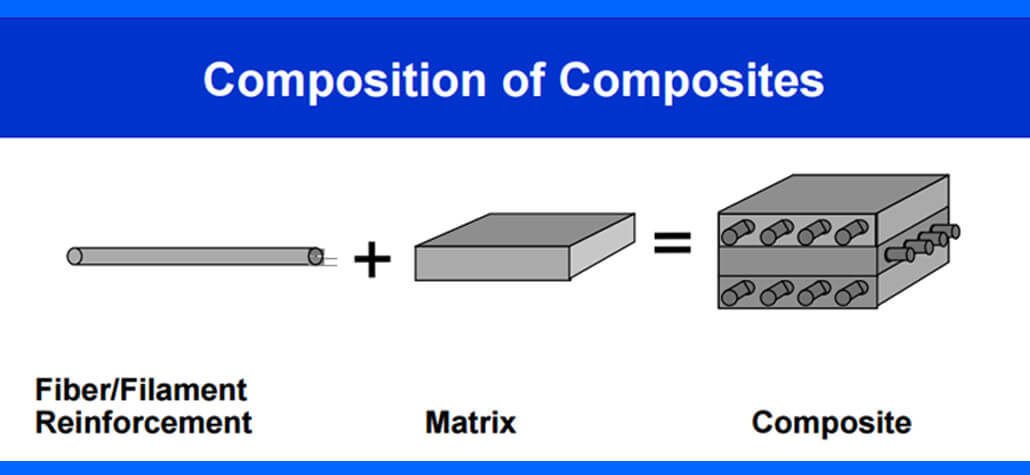

A composite material is a chemical combination of two or more different materials with an interface between them. One material is called matrix and the second is called reinforcement. The reinforcement is added to the matrix to improve or modify its properties. The reinforcement is the discontinuous phase, evenly distributed throughout the matrix volume.

Fibers give the assembly the characteristics of resistance to stress. In comparison with the matrix, the effort that can be taken is far superior. The matrix has a much larger elongation and resilience that ensures that the fibers break before the matrix yield.

Plastic material is a synthetic material made from a wide range of organic polymers such as polyethylene, PVC, nylon that can be moulded into shape while soft, and then set into a rigid or slightly elastic form.

Thus, a plastic material is totally different from a composite material by having 1 element inside of it’s structure compared with 2 elements of reinforcement and matrix that make a composite.

There is only one material in the rail market that is defined and behaves as a composite and that is RAILKO, manufactured at Tenmat.

3. UIC 510-1 Appendix 8 Interchangeability characteristics of sprung side bearers and pivot bearings for 2 axle bogies suitable for a load of 20t or 22.5 per axle:

3.1 . First mandatory condition is :

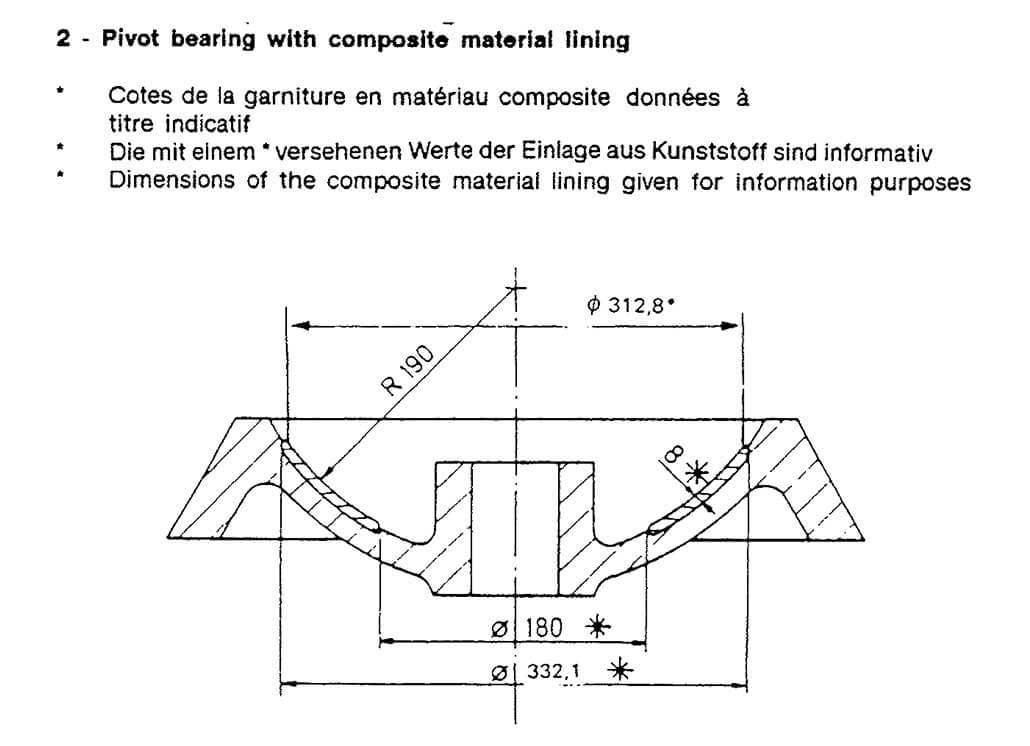

3.2. Second mandatory condition:

3.3. Rotational Torque:

4. Conclusions:

– Plastic material is not specified at all in UIC 510-1.

– UIC 510 – 1 refers to composite material ONLY and not plastic.

– Side Bearer Liner metal “Housing” shall (as mandatory) incorporate composite material lining.

– Second point from Appendix 8 of UIC 510-1 refers to composite liner for pivot as well.

– Side bearer liners and centre pivot liners must be from SAME COMPOSITE MATERIAL in order to have a rotational torque in the specified limit. These two components work together and cannot be separated. Please note that conditions in points 1 & 2 , Appendix 8 of UIC 510-1 (must be complied to have this rotational torque: composite material and NO plastics)

– The only way to fulfil the Interchangeability conditions defined in UIC 510-1 is to use composite material. By Using plastic you will be outside of UIC specification and under risk of not having a rotational torque as Interchangeability characteristic.

Please contact us here for any rail-related composite materials enquires you may have.”