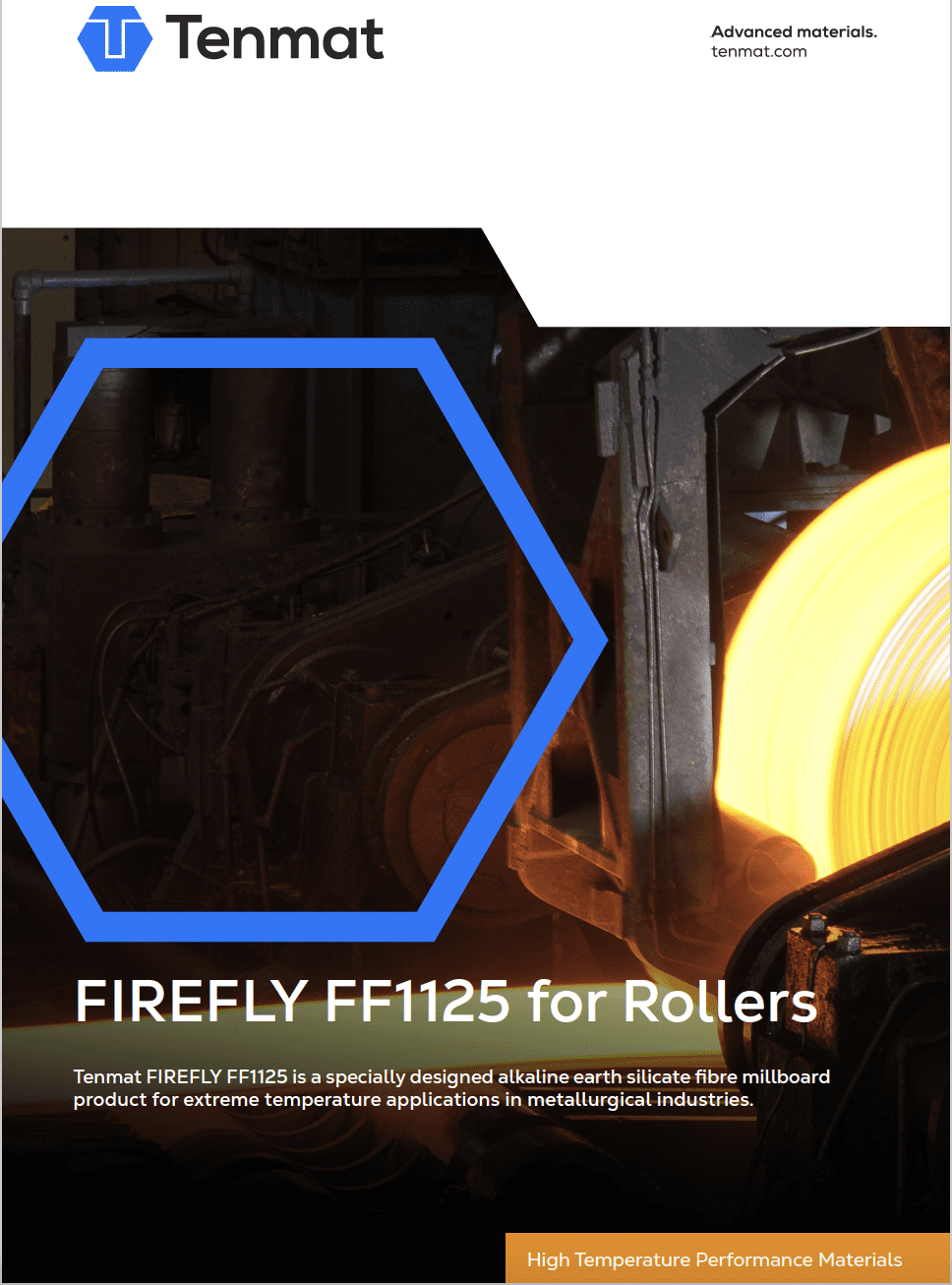

FIREFLY MILLBOARDS

A first choice for thermal insulation applications

Wet-laid, clay-bonded, inorganic mineral fibre boards are available in typically 1m x 1m square sheet format in thicknesses from 1.5mm to 12mm. All ranges possess high-temperature capability, in excess of 1000°C, and low thermal conductivity (K value), typically 0.12 W/mK, making them a first choice for thermal insulation applications.

At a density of typically 1,000 kg/m3, they are rigid, and strong, and can be used in sheet form or cut to produce gaskets and seals.

They are all exonerated products in accordance with the European Directive 97/69 EC on Classification, Packaging, and Labelling of Dangerous Substances.

Tenmat Firefly products are used worldwide in iron & steel foundries, melt shops, metallurgical and pouring control systems, and feeding systems.