Giel-Don Bosco Agricultural College, Normandy, France

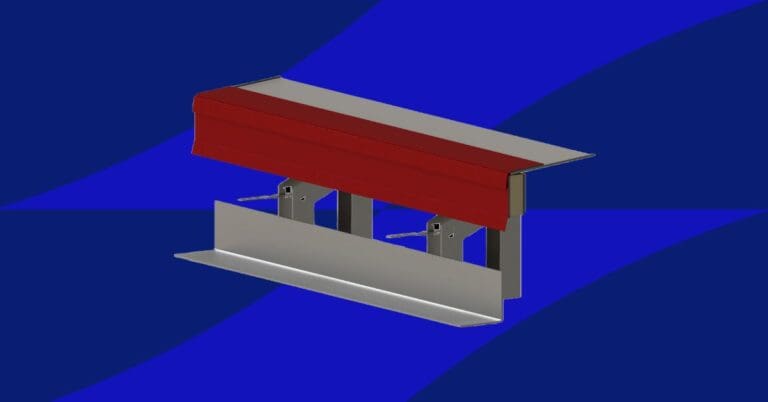

Ferobide wear part reinforcing tiles combine tungsten and steel. This alloy allows the plates to be welded directly to the farm on the parts to be protected. Moreover, even if the material is hard, it can be cut to fit the parts to be protected.

Easy to weld Ferobide Tiles for the protection of wear parts.

[vc_row][vc_column][mk_padding_divider size=”20″][/vc_column][/vc_row]

The Test

Tenmats exclusive agent in France Mr Patrice Gendre, provided sample tiles of Ferobide, so an independent test could be conducted at Giel-Don Bosco Agricultural College in Normandy. A Varilarge 4 non-stop hydraulic body plough was equipped with standard carbide tips. Half received the reinforcement of two Ferobide wafers by simple welding. The eight tips were weighed before work commenced. After ploughing 25 ha of a very stony clay-loam soil, at 7 km / h, the 8 points were dismounted and weighed a second time. The result is that the spikes protected with Ferobide Tiles had lost only 11.4{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} of their mass, compared to a loss of 24.09{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} for the spikes using only the standard carbide tips.

Reinforced points with Ferobide Tiles after 25ha of ploughing in very stony clay soil.

[vc_row][vc_column][mk_padding_divider size=”20″][/vc_column][/vc_row]

Author: Pierre-joseph Delorme – journalist for Entraid

Reference: https://www.entraid.com/articles/pieces-dusure-ferobide-renforcer