FEROBIDE is a weldable tungsten carbide composite material, which combines high levels of wear resistance with the ease and reliability of a weldable material. The unique features of FEROBIDE closes the gap between conventional tungsten carbide which requires brazing and weldable materials which have a significant lower wear performance.

AGRICULTURAL APPLICATIONS

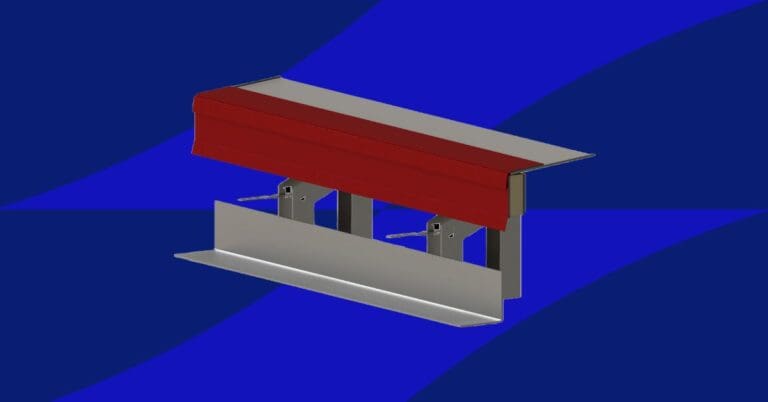

Agricultural applications face many different challenging wear situations. Ferobide has showed its capabilities in ground engaging applications on subsoilers, cultivators, ploughs, harrows and drills as well as on scrapers.

Ferobide is also very complimentary to regular tungsten carbide tipped tools where it is used to protect the steel parts of the tool to balance the wear rates and reach a significantly improved life span.

BEYOND TRADITIONAL TUNGSTEN CARBIDE

TENMAT initially developed innovative FEROBIDE wear protection over 8 years ago to resolve the major limitations of traditional tungsten carbide materials often used on Agricultural Machinery Points. FEROBIDE has experienced successful development at TENMAT’s in-house R&D technical laboratory alongside positive field testing across all types of soil and machinery application under challenging working conditions.

Unlike traditional tungsten carbide, FEROBIDE uses a steel matrix to bond tungsten particles together. The unique forming process yields very high wear resistance combined with a superior impact and chipping resistance. FEROBIDE consists of high-quality tungsten carbide, with a typical hardness of 1500 HV.

Read case studies, testimonials and learn more by visiting Ferobide website.