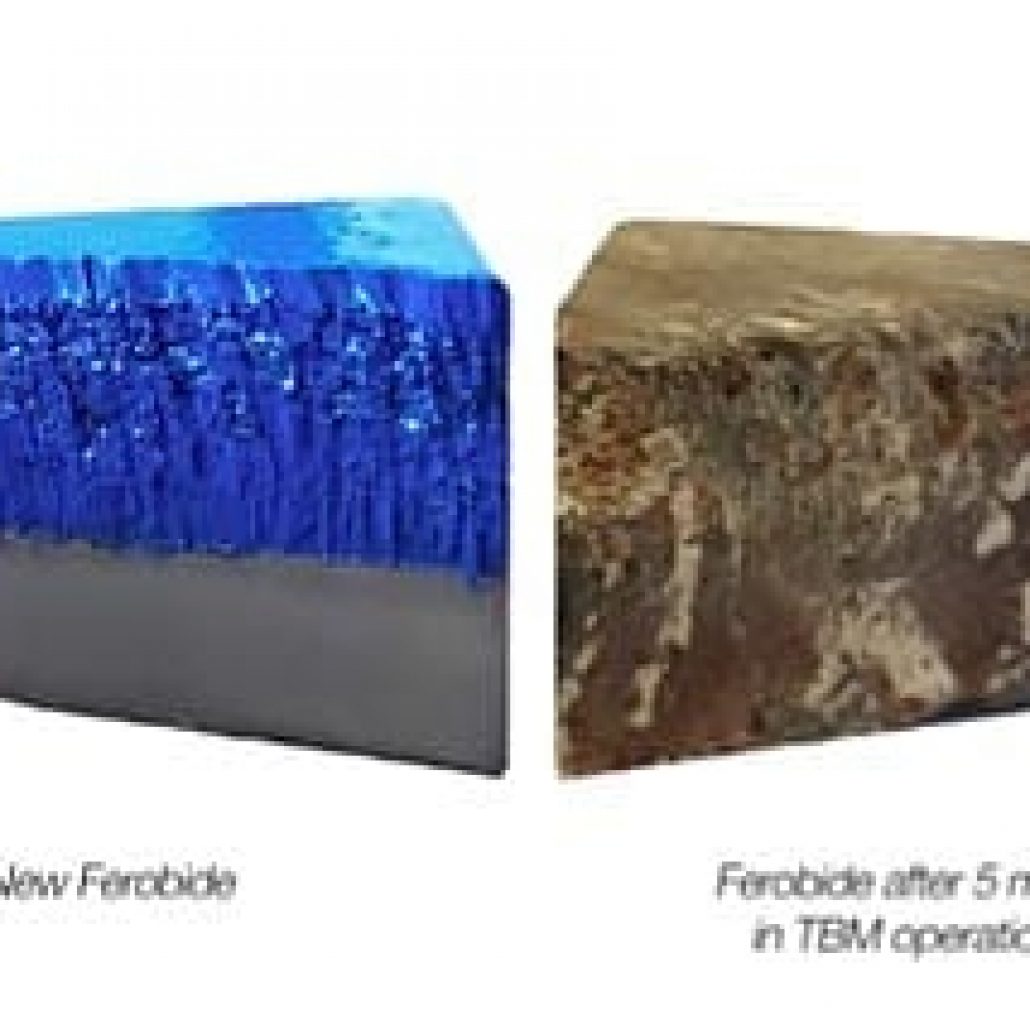

FEROBIDE is a weldable tungsten carbide composite material, which combines high levels of wear resistance with the ease and reliability of a weldable material.

The unique features of FEROBIDE closes the gap between conventional tungsten carbide which requires brazing and weldable materials which have a significant lower wear performance.

FEROBIDE is ideal in situations where brazing is not an option and for applications involving sliding wear. FEROBIDE has found its use in critical applications in several different industries such as agriculture, separation, mining, mixing, mineral processing and road maintenance.

The material is available in a range of standard tile sizes with custom designs available upon request.

ASTM G65 Data

FEROBIDE has been tested at renowned NPL, National Physical Laboratory, according to the ASTM G65 standard. Typical results in such tests are 3mm³ of wear. This is comparable to that of tungsten carbide with high (~10%) cobalt content.

Sliding Wear Test

FEROBIDE has a low friction coefficient and protects the surface of a steel counter face from wear, making it ideal for sliding conveying applications, like those found with drag chain conveyors. The table and photos below show the sliding wear behaviour of FEROBIDE on FEROBIDE, Steel on Steel and FEROBIDE on Steel:

| Sliding wear performance | Wear of pad in mm per km | Relative wear performance | Wear of counter face in mm per km | Relative wear performance |

|---|---|---|---|---|

| FEROBIDE pad on FEROBIDE counter face | 0.3 | 79 times longer life of pad | n/a | n/a |

| Hardened steel pad on hardened steel counter face | 22.8 | – | 7.6 | – |

| FEROBIDE pad on hardened steel counter face | 0.03 | 711 times longer life of pad | 0.4 | 19 times less wear of counter face |

Typical Relative Wear Performance

When compared to other common wear resistant materials in G65-type abrasion tests, FEROBIDE is:

- 15 times better than 500 HB hardened steels

- 8-10 times better than chromium carbide plates

- 6 times better than cast white iron

- 4 times better than 97% alumina

*Based on internal test rig.

LEARN MORE

WELDABLE

FEROBIDE is weldable. This means that there is no need for brazing; a common cause of carbides failure resulting from the weak braze joints.

WEAR RESISTANT

FEROBIDE is extremely wear resistant. The components consist of an advanced organometallic composite that offers extraordinary resistance to abrasion, which means longer wear life and greatly reduced machine downtime.

TOUGH

Used in the most demanding industrial applications such as agriculture, crushing, shredding and construction, FEROBIDE has unprecedented toughness, impact resistance, and durability.

AVAILABILITY

FEROBIDE Tiles are available in the following dimensions

| 4mm Thickness | 6mm Thickness | 8mm Thickness | 12+mm Thickness |

|---|---|---|---|

| 8 x 40 | – | – | – |

| 15 x 40 | 15 x 40 | 15 x 40 | – |

| 25 x 60 | 25 x 60 | 25 x 60 | 25 x 60 |

| 40 x 40 | 40 x 40 | 40 x 40 | 40 x 40 |

2D shapes are also possible with bespoke tooling. Contact us for more information.